Produced Watre Treatment & Field Injection

Produced Water Treatment—CFU

As the exclusive partner in China for the sales and fabrication of Cameron TST CFU unit for the Chinese market, TDS cooperates with Cameron-TST to promote the New Generation CFU technology in Asia Pacific Region. TDS can provide the complete water treatment solutions and services for the customers, including the design, process guarantee and mechanical guarantee for water treatment system, the fabrication, installation and commissioning for CFU package.

The type select and design of the New Generation CFU technology can be realized with respect to the variable requirement of the composition of the produced water, capacity, oil in water content, temperature and oil droplet size distribution.

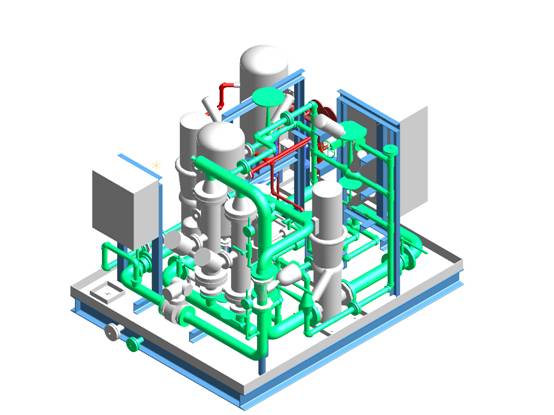

3D Model of CFU

3D Model of CFU

l

l Advantages:

What’s new Generation?

What’s new Generation?

n Multiple separation stages within one vessel

n Need for several vessels in serial is eliminated

n Handle higher OIW inlet concentration

n No tangential inlet. Flexible diameter /height ratio

n More flexible design and cheaper fabrication

n Less space required and easier adaptation into existing installation

n Multiple internal feed distribution

n Better internal mixing and contact between gas bubbles and oil droplets

n Less sensitive to scaling up vessels

n No conflict with existing patents. The technology is worldwide patent pending.

l Applications:

The solution could be a standalone technology replacing the whole traditional water train. It could be replacing part of the existing system, be in parallel when there is a need for increased capacity or it could act as a polishing unit downstream of existing technology.

l CFU Pilot Test:

If possible, TDS would always recommend a pilot test. The test unit has a weight of only 300 kg and is easy to transport to the platforms. Based upon data received before the test, we would be able to recommend a test program including tie in points, number of stages, etc. The test results will give you the exact performance of a full scale unit and will give valuable information both for us and for the Operators. A test is normally performed in 3-4 days.